TEREX’ mission is to make innovative products. For over 40 years the TEREX Group has been manufacturing roadheading machines with cutting heads for mining and tunnelling operations.

In the field of hydraulic transverse cutting units TEREX is the world-wide market leader and epitomises cutting-edge tech- nology made in Germany.

From civil engineering to landscape gardening – TEREX‘ cutting units show their strength and flexibility in a multitude of appli- cations. Various hydraulic motors and cutting heads can be attached to TEREX | Schaeff cutting units, enabling an optimum adjustment to operate conditions.

The product range comprises seven types of transverse cutting units with hydraulic drive powers of 30 HP, 40 HP, 60 HP, 80 HP, 120 HP, 160 HP and 200 HP respectively.

TEREX also offers solutions for special applications, such as cutting drums and slot cutting drums in various widths and diameters, drums for cutting tree stumps, and anti-dust systems for indoor operations. Behind TEREX’ products you will find a network of distributors who know the business inside out. Local dedicated service and support teams offer customers professional support before, during and long after the sale.

INNOVATIVE ENGINEERING – INDIVIDUAL SOLUTONS – COMMITTED CUSTOMER SERVICE OFFERING 1) Extremely economic 2) Extremely accurate cut 3) Low vibration FOR SENSITVE 4) Low noise 5) Suitable for underwater operations 6) Low maintenance 7) Suitable for narrow and deep trenches 8) Recycling of excavated material ADVANTAGES OF CUTTING TECHNOLOGY HYDRAULIC TRANSVERSE CUTTING UNITS TRUE ALLROUNDERS

THIS GRINDER IS FOR:

Medium-hard to hard rock and concrete

Wear-protected spiral blade for limited pick penetration, lower vibration and smoother operation

Boom extends from 14 – 20 feet and 45 degree swivel dipper for mounting of tunnel boom equipment such as a drum grinder for excavation of tunnel material in a low profile configuration

This custom built unit is composed of

•a basic low height boom set up for the factory double lift rams and integrated dipper ram •a tunnelling swivel dipper mount which rotates 2×45° either way • mounting for a dipper stick with double lift rams

Length of the standard boom to dipper mounting is 4200 mm (14 feet) extending to 6100 mm (20 feet)

Dual cylinder mounting swivel dipper stick can be custom built to accept any double drum or mondrum grinder

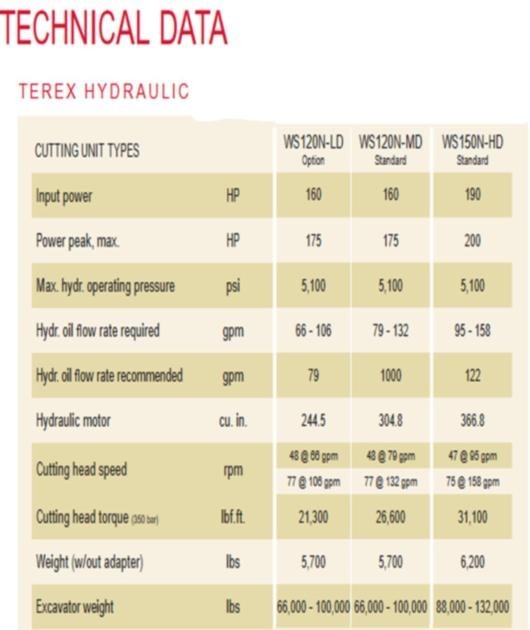

We were going to mount our TEREX WS-120MD Dual drum ginder head on this unit for tunnel and low overhead overhead excavation work.

All hydraulic lines c/w quick couplers for dipper mounted equipment included as well as water feed lines.

Unit is in excellent condtion.

AS WITH ANY CUSTOM-BUILT EQUIPMENT THIS IS EXTREMELY EXPENSIVE OVER $400,000.00 TO REPLACE

WE JUST DROPPED THE PRICE BY MORE THAN $50K AS WE ARE LEAVING BC FOR NB DUE TO HEALTH ISSUES FROM THE SMOG IN THE FRASER VALLEY

TAKE BOTH UNITS FOR $50,000.00

OR TAKE THE CRINDER FOR $40,000.00 AND THE BOOM FOR $10,000.00

BOTH UNITS WHICH ARE IN PERFECT CONDTION ARE SITTING AT S AND L WELDING MISSION BC (copy and paste)

http://www.slwelding.com/

WHO WOULD MODIFY IT TO FIT YOUR MACHINE QUICKLY AND REASONABLY.

THIS WOULD MAKE FOR THE LARGEST LOWEST HEIGHT GRINDER BUILT FOR TUNNELING AND FOUNDATION WORK IN LOW TIGHT AREA LOCATIONS

S AND l WHO DOES ALL OUR WORK AND WAS GOING TO MOUNT THIS ON AN HITACHI USLR 345 SHORT TAILSWING EXCAVATOR FOR US – BUT DUE TO THE SMOG AND TRAFFIC IN THE FRASER VALLEY, WE ARE LEAVING BC FOR NB WHERE WE BOUGHT A NEW HOME.

THESE UNITS MOUNTED ON A 345 HITACHI 345 USRL OR 400-470 CLASS EXCAVATOR WOULD RENT OUT FOR $600.00 PLUS PER HOUR AND WORK WHERE VERY FEW MACHINES COULD.

FRANK 604-476-7777

We can supply trucking anywhere in North America Except Mexico – we get great rates